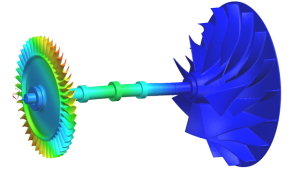

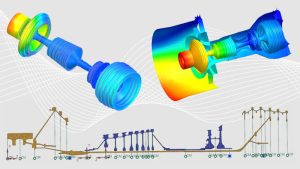

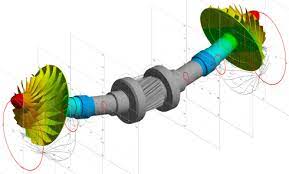

Once a turbomachine has been designed for the best compromise of thermodynamic and aerodynamic efficiency, space, weight, and structural constraints, it should be checked for rotor dynamics to ensure no destructive vibrations in the rotor-bearing-support system. We provide consulting for rotor dynamics which span a multitude of different equipment.

These services meet International Organization for Standardization (ISO) standards. Our engineering experts have performed rotor dynamic analysis and worked on vibration problem-solving for over 12 years. Here at Godwin, we can carry out extremely complicated studies related to unbalanced rotating mass behavior to save you precious time.

Other rotor dynamics service capabilities include:

- Calculations of lateral, axial, and torsional vibrations

- Campbell diagram analysis for damped and undamped systems

- Unbalance or transient response calculations

- Computation of rotor system with clearances, full and partial rubbing, external and internal friction, and definition of instability thresholds

- Computation of rotor system with nonlinear journal/rolling bearings, squeeze-film dampers, and many other types of rotor studies

These simulations will help maintain performance, stability, and reliability.